|

Dpair Power Hardware Machinery Co., Ltd.

|

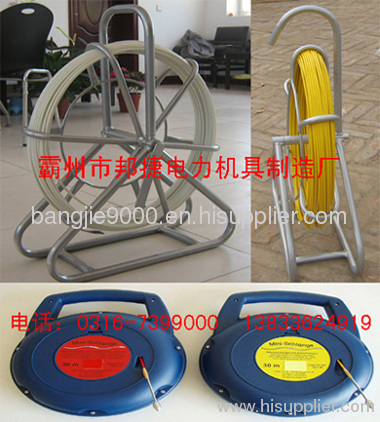

FISH TAPE

| Price: | 0.1~3.0 RMB |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Brand Name: Bangjie

Material: PVC and Fiberglass

Specification: diameter from 4.5mm-16mm for choice and lenght from 30-500 meters for choice

introduction of duct rodder:

Duct rodder are composed of fiber glass rod which is extruded by fiber glass and high strength resin at high temperature. This type of rod has high tensile strength and flexibility. It was covered by a high density polyethylene engineering plastic as its protect layer, which make duct rodder cover sliding on surface, durable,corrosion resistant and has good insulation performance, which make them safe for using in cable occupied duct. High Density polyethylene(grade: for insulating and jacketing of Telecommunication cables) is used in the outer diameter coating. Duct rodder will be equipped with different size reel according to the length of rod. There are wheels on the reel, which make it convenient for moving.

Features and Benefits:

1. Light weight, durable, resistance to acid and alkali, aging resistant, corrosion resistant.

2. High tensile strength and bending properties, which make it go through narrow pipes easily.

3. Perfect temperature adaptability, the product will not soften in hot weather or become brittle in the cold weather.

4. Cover was coated with long-term UV-resistant polyethylene.

5. There are meter marks on the surface of duct rodder, which can be used for measuring distance.

6. There are several colors for your choice.

Technical Data of Duct rodders :

Property | value |

Model specification | 4.5mm,6mm,8mm,10mm,11mm,12mm,13mm,14mm,15mm,16mmfor your choice, and we can also accept OEM order |

Length | 30,50,60,80,100,120,150,180,200,250,300,350,400,450,500 meters for choice. |

Material | Fiberglass (inner) and high density polytgtkebe(outer) |

Density | >1.9gr/cm3 |

Working temperature | - 40 to + 80 |

Minimum pulling strength | 4000 N±5% |

Tensile Modulus | >46.500Mpa |

Consistency of rod | 137gr/m |

Flexural Modulus | >46.500Mpa |

Elongation at Break | 2.5-3% |

Min. Bending Radius | 388m |

Tensile Strength | >15N/mm2 |

Environmental Stress & Crack Resistance | >1000hr |